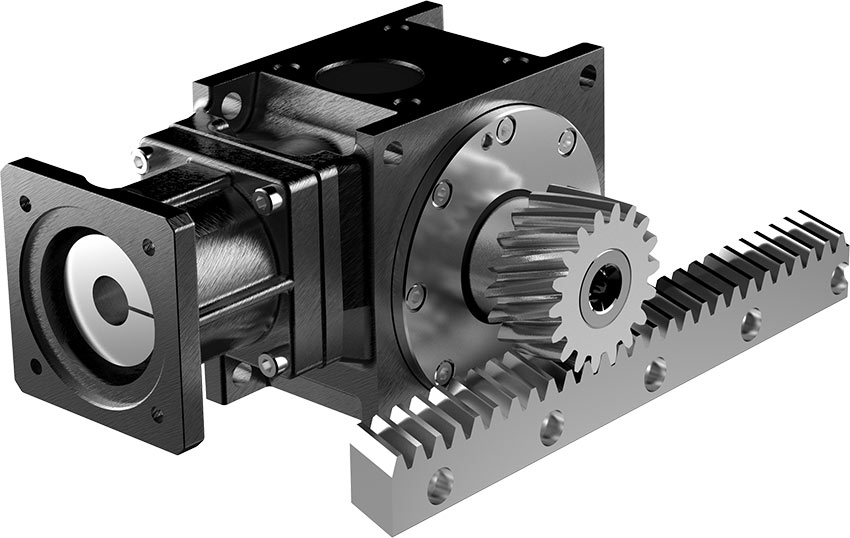

Rack and pinion drives are commonly used in large gantry robots and material handling systems for their ability to achieve high-speed movements over long travel lengths. The most common rack and pinion systems for industrial automation consist of a linear rack (also referred to as a “linear gear”), a pinion (also referred to as a “circular gear”), and a gearbox.

Image credit: MS-Graessner GmbH & Co.

Although rack and pinions can use either straight- or helical-cut teeth, helical teeth are often the preferred choice since they provide higher load capacity and quieter operation. Helical gears also have very small tooth pitch errors – in the range of single microns – for very low backlash.

Image credit: MultiCam Canada

Leave a Reply

You must be logged in to post a comment.