Image credit: IKO

The basic distinction between “standard” and “miniature” profiled rail guides is the width of the guide rail: profiled rails with a width of 15 mm or less — and the carriages that fit on them — are generally considered “miniature” by bearing manufacturers. (However, some manufacturers also produce 15 mm rail guides in standard versions, as we’ll explain below.)

In addition to the width of the rail, there are other key differences between standard and miniature profiled rail guides and carriages that designers and users should be aware of when specifying linear motion components.

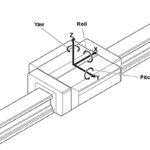

Ball and raceway construction

First is the basic construction of the carriage, or runner block. Most standard profiled rail carriages use four rows of balls — two on each side of the carriage. But because of their compact dimensions, miniature versions use only two rows of balls — one row on each side of the carriage. This means that miniature profiled rail carriages have relatively lower load and moment capacities than would be expected of four-row carriages.

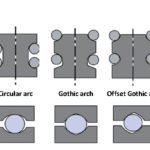

Image credit: Schneeberger

To help counter the loss of two ball rows, miniature guides typically use Gothic arch raceway geometry, which provides four points of contact between the balls and the raceway. This ball-raceway geometry gives the carriage the same load capacity in all four directions — downward, lift-off, and side loading — and provides relatively high moment load capacities.

Image credit: Nippon Bearing

Materials

Another difference between standard and miniature profiled rail guides concerns materials. Where standard profiled rail guides and carriages are made primarily from steel, miniature versions are offered as standard in stainless or corrosion-resistant steel — for both the guide rail and carriage, and in some cases, even the balls and recirculation pieces. This is especially beneficial in applications where corrosion-resistance is necessary, such as those involving chemicals, occasional exposure to water or high humidity, or even industry-specific requirements for stainless steel materials, such as those found in the food and packaging and medical industries.

Image credit: Schneeberger

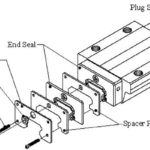

Sealing

Manufacturers also take different approaches to sealing for standard and miniature profiled rail guides and carriages. For standard versions, manufacturers often focus on ways to keep even the finest dust and fluid mist out of the carriage and to retain lubrication as efficiently as possible.

Image credit: Chieftek Precision Co.

But miniature versions are often used in applications in the electronics, semiconductor, and medical industries, where the environment is relatively clean or may even be a certified cleanroom. For this reason, miniature profiled rail carriages are typically offered with several sealing options, including the option to omit seals altogether.

For those applications that do require protection against contamination and loss of lubrication, some manufacturers now offer miniature rail carriages with end cap seals that incorporate a lubrication reservoir, to reduce maintenance intervals and ensure sufficient sealing for contaminated environments.

Preload and accuracy class

Miniature rail carriages also have limited preload and accuracy class options. First, because of the small size of the balls used in miniature versions, preload is typically limited to 1 to 2 percent of the dynamic load capacity (as opposed to 8 or even 13 percent for standard versions), with clearance (slight play between the carriage and the rail) or light preload being the most common options.

Similarly, miniature profiled rails are typically offered in “normal” and “high” accuracy classes, with some manufacturers offering “precision” as the highest accuracy class — unlike standard profiled rail assemblies, which are also offered in “super-precision” and “ultra-precision” accuracy classes.

Image credit: Bosch Rexroth

Image credit: Nippon Bearing

Feature image credit: Ewellix

Leave a Reply

You must be logged in to post a comment.