Microstepping is a method of controlling stepper motors, typically used to achieve higher resolution or smoother motion at low speeds.

Stepper motors move in discrete steps, or fractions of a revolution. For example, a stepper motor with a 1.8 degree step angle will make 200 steps for every full revolution of the motor (360 ÷ 1.8). This discrete motion means the motor’s rotation isn’t perfectly smooth, and the slower the rotation, the less smooth it is due to the relatively large step size. One way to alleviate this lack of smoothness at slow speeds is to reduce the size of the motor’s steps. This is where microstepping comes in.

Microstepping control divides each full step into smaller steps to help smooth out the motor’s rotation, especially at slow speeds. For example, a 1.8 degree step can be divided up to 256 times, providing a step angle of 0.007 degrees (1.8 ÷ 256), or 51,200 microsteps per revolution.

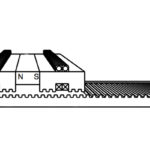

Microstepping is achieved by using pulse-width modulated (PWM) voltage to control current to the motor windings. The driver sends two voltage sine waves, 90 degrees out of phase, to the motor windings. While current increases in one winding, it decreases in the other winding. This gradual transfer of current results in smoother motion and more consistent torque production than full- or half-step control.

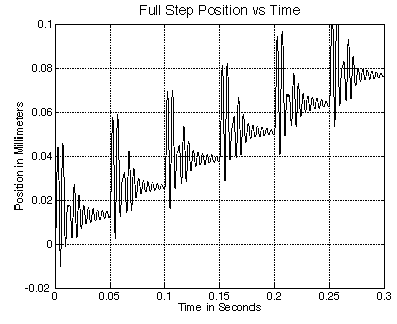

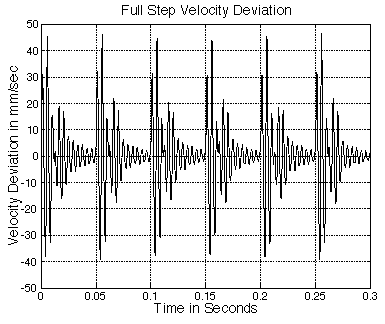

Images credit: Dover Motion

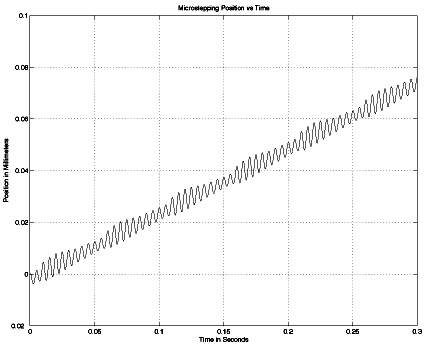

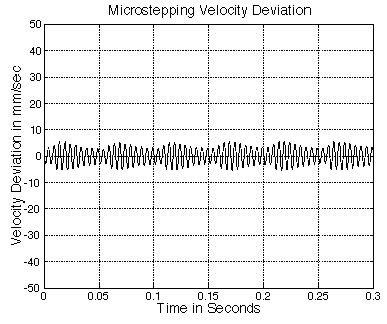

Images credit: Dover Motion

While the smoothness of torque delivery, low-speed motion, and resonance are improved with microstepping, limitations in control and in motor design prevent them from reaching their ideal characteristics. This is primarily because microstepping drives can only approximate a true sine wave, so some torque ripple, resonance, and noise remains, although each one is greatly reduced in comparison to full- and half-stepping modes. In addition, torque production from a stepper motor with microstepping control is only about 70 percent of the torque produced with full-step control.

Microstepping is sometimes considered a good alternative to mechanical gearing because it does not introduce backlash into the system or reduce the system’s maximum speed. However, mechanical gearing multiplies the torque from the motor and increases its position-holding capability.

It’s important to avoid what is sometimes referred to as “empty resolution,” where the division level of the steps (i.e. the resolution) is higher than practical for the system constraints. This most often occurs when the torque produced by the microstep is insufficient to overcome the friction torque of the component that’s being driven (such as a leadscrew or ball screw). The incremental torque per microstep is determined by the following equation:

![]()

Where:

TINC = incremental torque produced with each microstep

THFS = holding torque (full-step operation)

SDR = step division ratio (number of microsteps per full step)

For a motor with 0.35 Nm holding torque using a 256 step division ratio (SDR), the incremental torque produced by each microstep would be 0.002 Nm.

![]()

![]()

If the screw has a friction torque of 0.06 Nm, it will take 30 microsteps (0.06 ÷ 0.002) to generate enough torque to cause the screw to move. In addition, operating with more steps per revolution requires a higher frequency for the pulse train driving the motor. Using the 256 SDR in the previous example means the motor takes 51,200 steps, or pulses, per revolution (200 full steps per revolution x 256 microsteps per step). At a motor speed of 100 rps (6000 rpm), the required pulse frequency is more than 5 MHz.

Feature image credit: Oriental Motor USA Corp.

It’s cool to learn about microstepping for stepper motors. I can see how it’d be better than mechanical gearing in some cases. Backlash to the system is probably a bad thing, in all regards. What exactly are these engines used for?

hello,

I’d like to know how you came up with the value of 256. please advise

Hello Guneish,

Several stepper drive manufacturers publish the capability to divide a 1.8 degree step into 256 microsteps, for 51,200 steps per revolution.

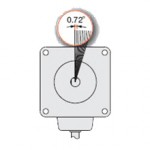

One manufacturer states in their literature that their drives are capable of dividing 0.72 degree step into 250 microsteps, for 125,000 steps per revolution! However, some experts argue that this resolution is not practical in most real-world applications.

Actually the pulse frequency would be just over 85Khz, not 5mhz. That’s 100 rpm, not rps.

Hello Larry,

You’re correct, that should be 100 rps (6000 rpm). Thank you for catching that!

how about correcting the 5mhz then?

Hi Janno,

Per the previous comment, the motor speed has been corrected to read 100 rps (not 100 rpm), so the frequency is correct. 51,200 pulses per revolution, multiplied by 100 revolutions per second, gives a frequency of 5,120,000 – or, just over 5 MHz.

Though pronounced the same, the correct spelling in this context is “discrete”, which means individually discernible, and not “discreet”, which means secret, clandestine. Sorry, I couldn’t resist the temptation to correct it.

Thank you Rio – I’ve changed it from “discreet” to “discrete” in both places.

Since most stepper motor drivers especially hybrid servo stepper drivers have dip switches to adjust sub-stepping to step division ratio (SDR) up 256 or 51,200 steps per revolution, I would assume that there are suitable controllers to match these drivers. Even for an equivalent two pole induction motor 50Hz synchronous speed of 3,000 RPM (50 RPS) 2.5Mhz pulse frequency will be required from the controller to drive the stepper motor.

Any suggestion of micro-controller with the capability to achieve 2.5 MHz or higher pulse speed?

Hi. I have a need for a stepper motor to rotate a circular object 15 degrees at a time. However, when a stepper motor has 1.8 degree steps things don’t line up correctly in the application. If the step degree was 1.5 degrees than all I’d need to do is make the code tell the motor to move 10 steps and it would be perfect. Is this something micro-stepping could accomplish?

You write, “While torque production, low-speed motion, and resonance are improved with microstepping control, limitations in control and in motor design prevent them from reaching their ideal characteristics… In addition, torque production from a stepper motor with microstepping control is only about 70 percent of the torque produced with full-step control.”

How is torque production improved but also only 70% of the torque produced with full-step control?

Hi Elena – In the first mention of torque production, I should have been more specific. The improvement related to torque is in smoothness of torque delivered by the motor, not in the overall level of torque. I’ve corrected the article to be more clear on that point. Thank you for catching that contradiction!