Synchronous belts are common in motion systems, providing smoother operation and better high-speed performance than chains and lacking the problems of slipping and stretching that can plague V-belts in precision applications. But one downfall of synchronous, or toothed, belts is the noise they produce. Although quieter than a chain drive, a synchronous belt can still generate noise […]

Linear drives (all)

How can lead screw backlash be reduced?

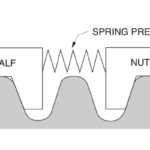

Backlash is an inherent property of lead screw assemblies due to the sliding motion between the screw and the nut. For some applications, a certain amount of backlash, or “play,” can be tolerated, but applications such as positioning, dispensing, or assembly often require a level of precision and repeatability that can’t be achieved if backlash […]

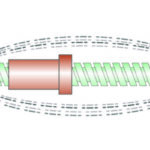

What’s the difference between ball screw critical speed and characteristic speed?

Ball screw drives incorporate two primary moving components: the rotating screw shaft and the nut that traverses the screw. (The radial bearings that support the screw shaft play a minor role for the purposes of this discussion.) This means that to accurately determine the maximum allowable speed of a ball screw assembly, there are two […]

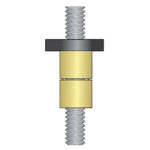

What is a follower nut, and what role does it play in lead screw operation?

Although the idea of a “follower nut” may seem to indicate that the nut serves a passive role in lead screw operation, it actually plays an important part in monitoring the condition and life of the screw assembly. The wear characteristics of a lead screw nut make the expected service life of the assembly difficult […]

When to use linear bearings and ball nuts with ceramic balls

Ball nut preload: What effect does it have on bearing life?

Ball nut preload offers several benefits to screw assemblies, but the most common reason for using a preloaded ball nut is to reduce axial play, or backlash, caused by clearance between the screw and nut raceways. Reducing this axial play does two things. It improves the repeatability of the screw assembly — meaning the assembly […]

Pick-and-place applications with Festo tools — showing at Pack Expo

Festo offers software and hardware to shorten packaging-machine development time and reduce engineering overhead. These components, systems, and software tools will be on display at Pack Expo on September 23 to 25 at the Las Vegas Convention Center Booth LS-6349. Design a pick-and-place robot and control cabinet in minutes Festo demonstrates a Cartesian robot and […]

How roller-screw and ball-screw actuators compare in high-force applications

As electric rod-style actuators overtake fluid power in a variety of high-force applications, it is important to understand how different screw technologies compare in the search for optimum performance and low life-cycle cost. By Daniel Schmit • Product Manager | Tolomatic Inc. Electric-rod actuators with either roller-screw or ball-screw technology are playing an expanding role […]

Bearing damage: What’s the difference between brinelling, spalling, and fretting?

Bearing damage, and ultimately, failure, can be caused by a variety of conditions, including improper mounting, poor lubrication, and overloading, to name a few. The mode of damage — what actually happened to the bearing as a result of detrimental conditions — is characterized by visible features, such as discoloration, wear marks, or pitting, on […]

Exlar GTX now with Hiperface DSL Stegmann absolute encoders

Curtiss-Wright Corporation’s Industrial Division announced that its Exlar facility, located in Chanhassen, MN, has added Hiperface DSL Stegmann absolute encoders as a part of their available Rockwell Automation feedback options. The GTX series joined the Exlar TTX, Tritex II, GSX, FTX, and K series Encompass product families in 2018. As an Encompass Partner, Curtiss-Wright and Rockwell […]