Ball screw drives incorporate two primary moving components: the rotating screw shaft and the nut that traverses the screw. (The radial bearings that support the screw shaft play a minor role for the purposes of this discussion.) This means that to accurately determine the maximum allowable speed of a ball screw assembly, there are two distinct factors that need to be taken into account: the critical speed of the screw shaft and the characteristic speed of the ball nut.

Ball screw critical speed

The critical speed of a ball screw is the first order natural frequency of the screw shaft.

A screw shaft will naturally experience some bending, or sagging, due to its own weight. As the screw rotates, it tends to vibrate, or whip (think of a jump rope), due to the combination of this bending and its rotational speed. If the screw’s rotational frequency matches its first order natural frequency, resonance can occur. This resonance, together with the bending, can cause serious damage or catastrophic failure of the screw assembly.

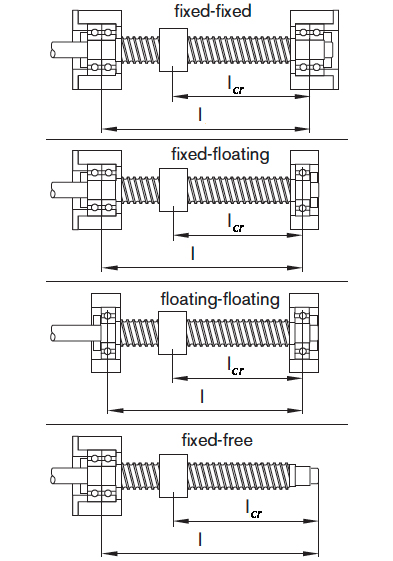

Critical speed depends on the screw’s end support method, its unsupported length, and its root diameter. Most manufacturers also recommend applying a safety factor — typically between 0.5 and 0.8 — to ensure the screw does not approach or exceed its critical speed.

Where:

nc = critical speed (rpm)

k = factor based on end support bearings

dn = root diameter of ball screw (mm)

Lcr = unsupported length of ball screw (mm)

It’s important to note that for ball screw assemblies with preloaded ball nuts, the nut acts as a fixed support, so the unsupported length (lcr) will be the greatest distance between the nut and the end of the screw.

Image credit: Bosch Rexroth

Another important point about critical speed is that it can typically be disregarded for assemblies in which the screw is stationary and the nut is driven. Although vibrations in the nut can be transmitted to the screw shaft — especially if the nut has high radial or axial runout — the effects on the screw will be small and can typically be disregarded.

Ball nut characteristic speed

Unlike the critical speed, which is determined by factors related to the screw shaft, the characteristic speed of a ball screw assembly is governed by factors related to the ball nut.

Specifically, characteristic speed is limited by the forces imparted on the balls during recirculation. These forces are determined by the mass of the balls and their speed as they travel through the nut, which depends on the ball nut design and the ball return method. Ball nuts with internal ball recirculation paths typically have higher characteristic speeds than ball nuts with external return circuits.

Characteristic speed is often referred to as the “DN” value of the nut because it is determined by multiplying the nominal diameter of the screw (d0) by the maximum allowable rotational speed (nmax).

![]()

DN values are specified by the manufacturer and typically vary between 60,000 and 150,000 mm/min depending on the type of ball nut. In sizing and selection, the DN value is used to determine the maximum speed (nmax) of a screw assembly based on the nominal diameter of the screw.

However, using the DN value to determine maximum speed may give invalid results for very small or very large diameter screws. In these cases, it’s important to check the manufacturer’s published maximum speed for the specific ball nut, diameter, and lead.

Leave a Reply

You must be logged in to post a comment.