Tribology is the study and application of the principles of friction, lubrication, and wear between two surfaces in relative motion. In linear bearing systems, those two surfaces are the bearing element and the guide raceway.

Friction and wear

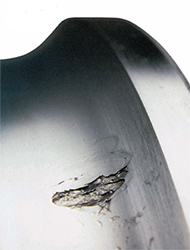

The term “wear” generally refers to deterioration, but when discussing tribology principles in relation to bearings, it refers to material loss on the bearing surfaces. Wear is an inevitable outcome of use, caused by the load, speed, and other operating conditions that the bearing experiences. The life of a linear bearing — whether recirculating or plain type — is determined by the amount of wear on the bearing surfaces.

Image credit: GGB Bearings and Bushings

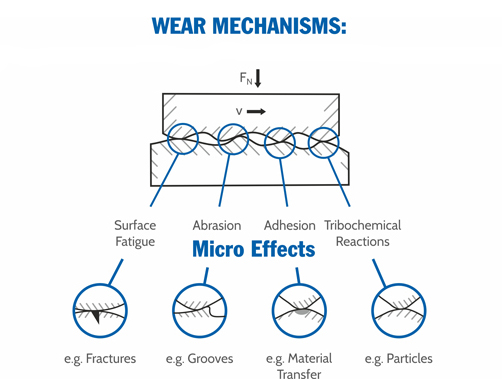

The primary cause of wear in bearing applications is friction. Although bearings are designed and manufactured to have extremely smooth surfaces, no matter how well the surfaces are finished and polished, they will inevitably have microstructures (also referred to as asperities), or “rough” spots, where the material dips and protrudes, much like the peaks and valleys of a mountain range.

Image credit: The Barden Corporation

As two bearing surfaces — a raceway and a ball, for example — move past each other, the “peaks” on each surface collide. This not only creates friction as the surfaces interfere, but the peaks can also break and release as particulates that abrade the bearing surfaces (through friction), causing premature fatigue failure.

By separating the bearing raceway from the rolling or sliding element (ball, roller, or plain bearing surface), lubrication reduces friction between the surfaces, which reduces wear and lowers the amount of heat generated. Lubrication also inhibits corrosion of the bearing surfaces and protects them against contamination.

Most people are familiar with friction as the force that impedes the movement of two bodies relative to each other (a book and a table, for example). But friction takes two forms: static (also referred to as “breakaway”) and dynamic (also referred to as “kinetic”). Static friction is caused by molecular bonding when two surfaces are in contact. Dynamic friction is caused by surface roughness. Lubrication plays a role in reducing both static and dynamic friction.

Tribology visualized: the Stribeck curve

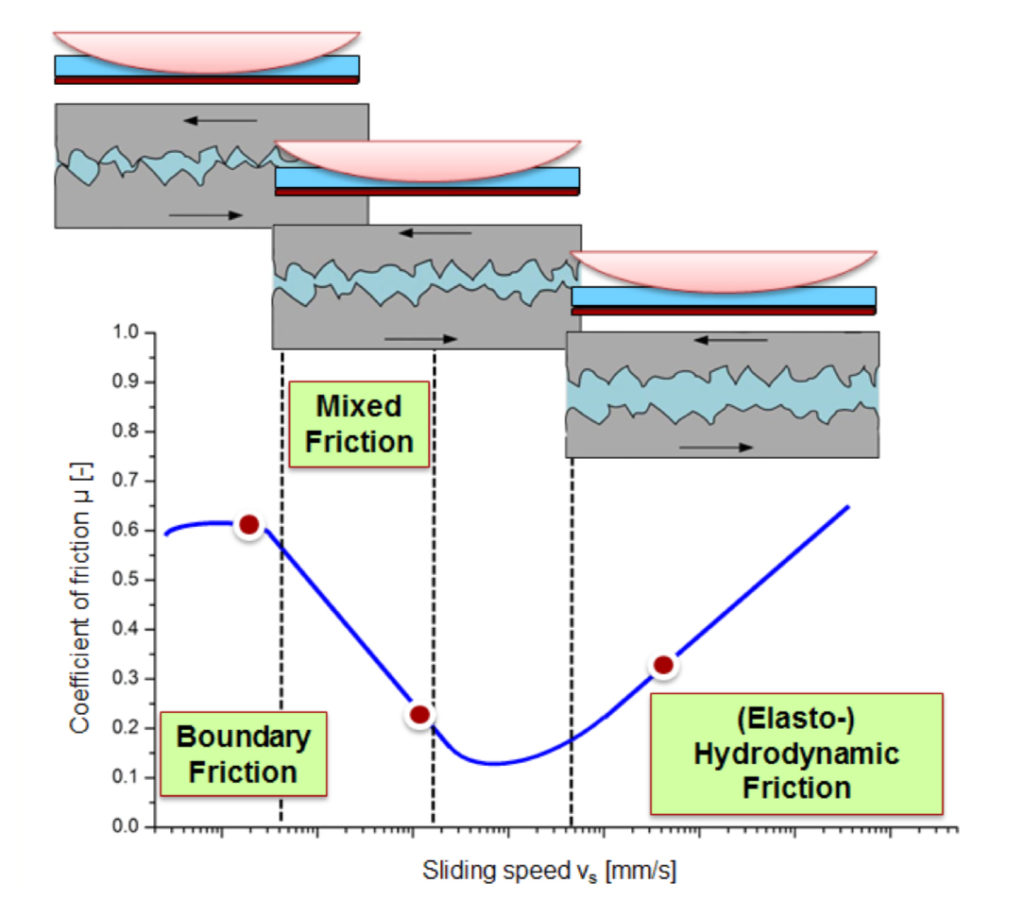

Different levels of lubrication develop between bearing surfaces, based on the lubricant’s viscosity, the pressure between the surfaces, and the speed of the bearing. The development of the lubrication film and the change in friction are shown on a Stribeck curve

Image credit: Anton Paar GmbH

When a bearing is stationary, lubrication is essentially squeezed out of the space (or lack thereof) between surfaces. Friction is high in this phase, due to the interaction between the two surfaces. This is referred to as boundary lubrication or boundary friction.

As the bearing begins to move, lubrication is pulled into the space between the surfaces. The pressure between the surfaces causes the lubrication’s viscosity to increase, and a thin lubrication layer develops between the bearing and the raceway. In some places, the lubricating layer separates the two surfaces, but in other places the “peaks” of the two bearing surfaces still contact. Friction is reduced, but it is not yet minimized. This is referred to as mixed lubrication or mixed friction.

Once the speed increases enough, the lubricating layer completely separates the bearing surfaces. In this phase of operation, friction is caused by shear of the lubrication rather than by surface interferences. This is referred to as elastohydrodynamic lubrication or elastohyrdrodynamic friction.

Lubrication options for linear bearings

Bearings are typically lubricated with either oil or grease. Grease adheres to surfaces better and lasts longer than oil, making grease the more common choice for rolling element bearings, such as recirculating ball and roller bearings. And because of speed’s influence on the development of the lubricating film, low-speed applications typically require grease since it provides better protection under the conditions of boundary lubrication and mixed lubrication, which are prevalent at low speeds.

Oil, on the other hand, dissipates heat better than grease, making it better for high-speed applications where heat generation is especially problematic. Oil can also be circulated through an external lubrication system that cools the oil and filters out any debris. It also flows more readily, making it better at lubricating complex structures and surfaces. But because of its low viscosity, it may not be a suitable choice for vertical surfaces, due to its tendency to pool at the lowest available space. An oil mist can address this problem but adds cost and complexity to the bearing system.

Plain bearings are often made from (or impregnated with) self-lubricating materials, such as PTFE (Teflon), Delrin, or nylon. But the release of lubrication from these materials isn’t consistent. And the sliding contact between plain bearing surfaces produces significant friction and heat. So while it is possible for some plain bearings to be operated without lubrication, the use of external lubrication can be beneficial, even for bearings that use self-lubricating materials — especially when the application involves high loads or high speeds.

Note that proper lubrication requires not only using the right type of lubrication for the bearing and its operating conditions, but also using the right amount of lubrication. Too much lubricant can actually increase friction and heat in the bearing and tends to trap particulates that can damage the bearing surfaces.

Leave a Reply

You must be logged in to post a comment.