Linear position feedback devices — also referred to as linear encoders — typically measure travel distances ranging from a few dozen millimeters to several meters. But when a positioning system has a very short travel — a few millimeters or less — traditional linear encoders are often too bulky or don’t provide the required measuring resolution. For these applications, capacitive sensors offer a compact solution that can measure position with nanometer-level resolution.

Rather than a scale and a read head, like typical optical and magnetic linear encoders, capacitive sensors are typically made from two metal plates with a dielectric, or insulating layer, between them — a design referred to as a parallel plate capacitor.

A capacitor is a device that stores electrical energy, and capacitance is a measure of how much charge the capacitor can hold. For parallel plate capacitors, capacitance depends on three factors: the overlapping area of the plates, the permittivity of the dielectric between them (typically air), and the distance between the plates.

![]()

C = capacitance (farads, F)

ε = permittivity of the dielectric (F/m)

A = area of overlap between the plates (m2)

d = distance between the plates (m)

When a voltage is applied to a parallel plate capacitor, a positive charge accumulates on one plate, and a corresponding negative charge accumulates on the other plate, creating an electric field between the plates. This field is monitored for changes, which indicate a change in capacitance.

Image credit: AspenCore

Because the dielectric separating the plates does not change, any change in capacitance is due to a change in geometry: either a change in the overlapping area of the plates or a change in the distance between them. A change in the overlapping area, “A,” indicates a change in planar displacement (movement of the plates relative to one another along parallel planes), whereas a change in the distance, “d,” indicates a change in axial displacement.

In most applications, one plate is made stationary and the other plate is attached to the object being moved, and the plates are arranged so that their overlapping area does not change. Therefore, any change in capacitance is a result of a change in the spacing between the plates and represents the distance that the moving object has traveled.

Capacitive sensors — also referred to as capacitive displacement sensors — are absolute position measuring devices, and since they measure the position of the moving part directly, linear and planar errors are eliminated, giving them very high accuracy with resolution in the nanometer — or in some cases, sub-nanometer — range. One example of their use is in optical inspection equipment, where the features being measured are at the sub-micron, or nanometer, level. Here, capacitive sensors are used to ensure the correct distance is maintained between the part and the measuring optics.

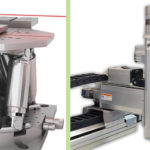

Because they can measure small distances and have very compact dimensions, capacitive sensors are often used in micro- and nanopositioning systems based on piezo motors or voice coil actuators. However, they’re not suitable for humid or wet environments, or those with significant temperature changes, since water has a different dielectric constant than air and can change the permittivity (ε) of the capacitor.

Leave a Reply

You must be logged in to post a comment.