The term “goniometer” can refer to a type of device that measures angles or to a device that rotates objects to a precise angular position. The former type, for measuring angles, is widely used in physical therapy to measure the range of motion of joints, such as the wrist or knee. This type of goniometer also has applications in science, for measuring the angles between crystal faces or for positioning samples and detectors for x-ray diffraction.

The latter type, for rotating an object around a fixed axis, is similar to a linear stage — but instead of providing linear motion in the X, Y , or Z axis, a goniometer stage produces partial rotation around a fixed point or axis above the stage. Rotation angles can range from as little as a few arc-seconds to as much as 90 degrees.

Common industrial uses for goniometer stages include micromachining applications and the alignment of mirrors for inspection systems. In laboratory applications, they’re often used for directing lasers and aligning mirrors or lenses in microscopy equipment, such as transmission electron and scanning electron microscopes.

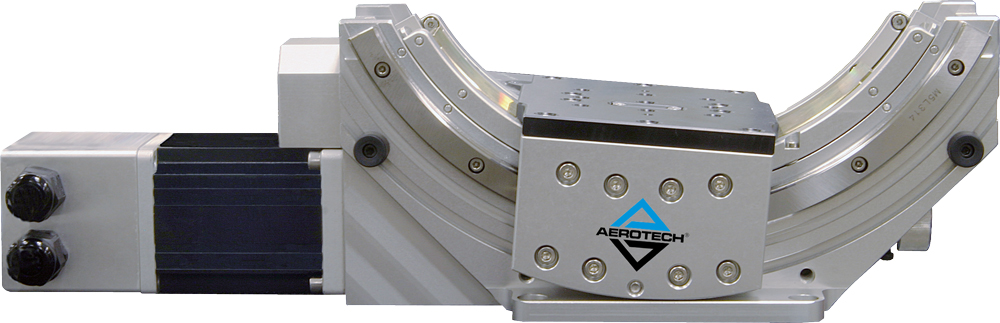

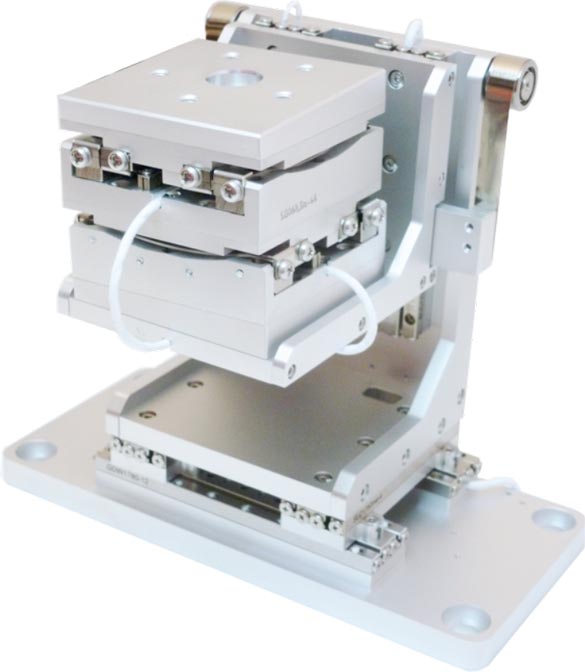

Like linear stages, goniometer stages come in a wide variety of designs, but every design incorporates a low-friction guide and a high-precision drive mechanism. The guide mechanism can be a curved dovetail bearing, a curved crossed roller guide, or even an air bearing. In some designs, bearing races are machined directly into the stage to form the equivalent of a partial, single-row rotary bearing that supports and guides the load.

Image credit: Nippon Bearing Co., Ltd.

The drive mechanism can be a high-ratio worm gear, a ball screw or lead screw (typically with an anti-backlash nut), or a direct-drive motor. Because goniometers are often used for very fine positioning, worm gear versions use very high ratios — in the range of 300:1 — and can be driven by hand with a micrometer or with a stepper or servo motor. Similarly, ball and lead screw versions use very small leads, and these are often driven by servo or stepper motors. Goniometer stages with crossed roller guides and piezo motors can provide ultra-high resolution for small ranges of motion to meet the needs of micro- or nano-positioning applications.

Image credit: Aerotech Inc.

One of the benefits of such a wide variety of designs is that goniometer stages can be used in a broad range of applications, including cleanrooms and vacuum environments.

Most goniometer stages are designed to allow stacking of multiple stages, providing orthogonal rotation around a common point. And in many cases, manufacturers of goniometer stages also manufacture linear stages and have made it easy to integrate the two types from a mounting and control standpoint, presenting designers with a pre-engineered solution that provides both linear and rotational movement.

Image credit: SmarAct GmbH

Feature image credit: Newport Corporation

I appreciate that you explained what the common industrial uses for goniometer stages are, including micromachining applications and inspection systems. I didn’t quite understand goniometer stages when it was explained during class. Your article does a great job of explaining these concepts.