Contributed FAQ courtesy H2W Technologies || Think of linear induction motors (LIMs) as rotary motors that have been cut and unrolled to generate linear instead of rotary motion. Linear induction motors are comprised of two parts, the primary and secondary, which interact with one another only when power is applied. Either the primary or the […]

FAQs + basics

Servo motor or stepper motor? How to choose

The overwhelming majority of linear motion applications (with the exception of pneumatically-driven types) use either a stepper motor or a servo motor to provide torque to the driving mechanism, which is typically a ball or lead screw, rack and pinion, or belt and pulley system. And unlike other components involved in linear motion, when choosing a motor, […]

When do you need a ball screw?

The gap is narrowing between applications that require ball screws and those that are suitable for lead screws, and it’s becoming more difficult for engineers and designers to determine which technology is best for their machine. Advances in lead screw designs and materials have given them higher load capacities and better positioning accuracy, making them a sound choice […]

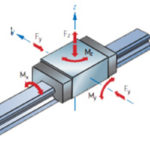

When is static load capacity important?

When sizing a recirculating bearing, most designers and engineers focus on bearing life, which is based on dynamic load capacity. This is the load at which a linear recirculating bearing will, with 90 percent certainty, achieve the targeted service life before fatigue occurs. Static load capacity, on the other hand, is the force that causes permanent […]

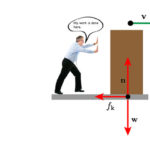

What is stick-slip?

Stick-slip, also referred to as “stiction,” is the bane of engineers and machine builders who need smooth, precise motion. Simply put, it’s the jerkiness that can plague both plain and recirculating linear bearings when they transition from standstill to motion. Here’s why stick-slip happens… When two objects slide against each other, friction works against their motion. […]

What is a PV rating?

When discussing bearing life, what comes to mind for most engineers is the standard L10 bearing life equation. But this equation was developed for bearings with rolling balls. (A similar equation exists for bearings that use rollers rather than balls.) For plain bearings, which have no rolling elements, determining the suitability of the bearing for a […]

Guide systems that turn corners

The shortest distance between two points may be a straight line, but some applications dictate moving in curved sections and around corners. When two or more axes are combined, as in a Cartesian or gantry system, a method of control called contouring can be used to create radii and round the corners of traditional rectilinear coordinates. […]

Voice coil actuator basics

Voice coil actuators are a type of direct drive mechanism that provides extremely precise positioning over small displacements. Like linear motors, they work on the principle of a permanent magnet field and a coil winding. When a current is applied to the coil, a force is generated. This force, known as the Lorentz force, is […]

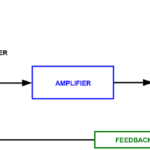

A servo system glossary for the mechanical engineer

Mechanical engineers are typically charged with designing, building, and applying a linear motion system for a specific machine or process. In doing so, our main concern is with attributes such as bearing life, deflection, and torque. And while we often work with the electrical and/or controls engineer for proper motor sizing and selection, rarely do […]