A rack and roller pinion system is a variation on the traditional rack and pinion that replaces the toothed pinion (gear) with a cage-type pinion that incorporates bearing-supported rollers. Each roller in the pinion is supported by two needle bearings, which eliminates the sliding friction that occurs in traditional rack and pinion systems. This greatly […]

Rack + pinion sets

Gallery: Rack and pinion systems – designs and applications

Rack and pinion drives are commonly used in large gantry robots and material handling systems for their ability to achieve high-speed movements over long travel lengths. The most common rack and pinion systems for industrial automation consist of a linear rack (also referred to as a “linear gear”), a pinion (also referred to as a “circular […]

Robot-transfer unit (RTU) and other linear-transfer system considerations

As robotics applications proliferate, robot integrators have begun to apply more 7th-axis tracks — also called robot-transfer units or RTUs — as well as linear tool-tray transfer systems. Benedict Talan • President | LazerArc of Motion Index Drives Robots excel in repetitive assembly and process operations that include welding, trimming, routing, drilling, fastening, composite layup, […]

What is Torque?

In this article, we answer the common question “what is torque?” Although torque refers to rotational motion, it is a fundamental concept in linear motion applications. Rotary motors produce torque, and when this torque is transmitted to a drive system – such as a screw, belt and pulley, rack and pinion, or chain and sprocket […]

Linear actuators: belt driven vs. rack and pinion driven

Belts and rack and pinions have several common benefits for linear motion applications. They’re both well-established drive mechanisms in linear actuators, providing high-speed travel over extremely long lengths. And both are frequently used in large gantry systems for material handling, machining, welding and assembly, especially in the automotive, machine tool, and packaging industries. Timing belts for linear […]

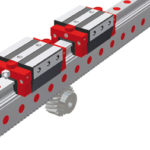

Profiled rail + rack & pinion = integrated solution

Profiled linear guides are typically used in conjunction with a drive system, such as a belt or ball screw, to provide rigid, accurate motion. When the specification calls for extremely long travel and high thrust force, the drive mechanism of choice is commonly a rack & pinion system. Fortunately for design engineers and machine builders, several […]

Designing (seventh-axis) linear motion tracks for robotic positioning

By Lisa Eitel • Robot-positioning tracks can add flexibility to manufacturing spaces, but must be fast, accurate, and safe to be truly useful. Here we take a look at drives that deliver. Robot positioning systems are long tracks in warehouse, aerospace, and automotive facilities to let one robot perform multiple tasks. Also called robot-transfer units or […]

Nexen offers new catalog featuring Versa thermoplastic rack

Nexen Group, Inc. introduces their latest Precision Motion Control Application & Selection Guide with an expanded range of products. This catalog offers complete performance data, sizes, specifications and technical reference on the company’s line of precision linear and rotary motion control solutions. It also includes Nexen’s newest addition to its lineup, the Versa Thermoplastic Rack. […]