Applications that require micron or sub-micron level positioning with extremely smooth motion and control often call for a direct drive system — linear motor, piezo motor, or voice coil actuator. Linear motor stages are typically used when high forces are needed over stroke lengths greater than a few hundred millimeters. But for high-precision applications with […]

FAQs + basics

How to account for rack and pinion inertia during system design

Rack and pinion drives are often used in applications that require stroke lengths beyond the practical limits of ball screws and thrust forces that exceed the capabilities of belt drives. And in some applications, rack and pinion systems can also provide lower total inertia than a suitable ball screw or belt drive alternative, which can […]

Linear motion basics: 13 fundamental topics you need to know

Whether you’re new to designing and sizing linear motion systems, or you could just use a refresher, we’ve gathered all the articles that cover mechanical concepts used in linear motion systems and put them together here, as a sort of “linear motion basics” reference guide. Unlike our curated lists of articles that address sizing and […]

What factors contribute to friction in linear motion systems?

Designers and engineers typically try to avoid or mitigate friction in linear motion systems. Although friction isn’t always bad — in some applications, it can provide a damping effect and help improve servo tuning — when it comes to linear motion systems, it increases the amount of force required to move a load, creates heat, […]

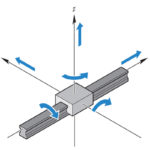

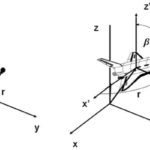

Degrees of freedom (DOF) basics for motion engineering

To identify the position of an object in three-dimensional space, we use a coordinate system that defines three axes: X, Y, and Z. If the object is a point mass, we only need three coordinates (X, Y, and Z) to locate its position. But a rigid body can both move, or translate, along these three […]

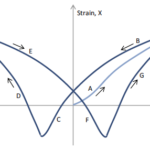

How does hysteresis affect piezo actuator performance?

Piezo actuators operate on the principle that application of an electric field (voltage) induces strain (displacement) in the material — a phenomenon known as the inverse piezoelectric effect. But if you plot the strain versus the electric field of a piezo material, you’ll see that the strain doesn’t follow the same path when the field […]

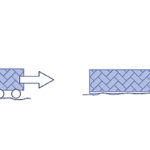

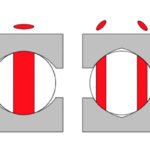

What makes a linear stage different from other types of linear motion systems?

Linear motion systems — consisting of a base or housing, a guide system, and a driving mechanism — are available in a wide variety of designs and configurations to suit almost any application. And because their designs are so varied, they’re often categorized according to key construction and operating principles. Case in point: The term […]

How to account for belt and pulley inertia during system design

In order for a motor to accelerate or decelerate a load, it must overcome the load’s inertia, or resistance to change in motion, as explained in Newton’s First Law. In belt-driven linear motion systems, the motor has to overcome not only the inertia of the applied load, but also the inertia of the belt, pulleys, […]

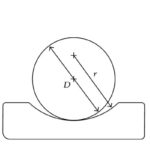

Motion basics: What is ball conformity in linear guides and screws?

In linear guides and ball screws, load-carrying balls or rollers can ride on planar (flat) raceways, as with non-recirculating linear roller bearings, or in curved raceways, as with ball screws and profiled rail guides. When a ball or roller rides on a planar raceway, the contact between the rolling element and the raceway will be […]

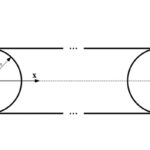

Motion basics: What is differential slip and how does it affect linear bearings?

Linear bearings that use balls or rollers are typically chosen for their ability to carry high loads with very low friction. But rolling elements — including linear bearings — are not friction-free. One of the factors that contributes to friction in linear bearings (along with properties such as surface roughness, elastic hysteresis of the materials, and […]