Whether you’re new to designing and sizing linear motion systems, or you could just use a refresher, we’ve gathered all the articles that cover mechanical concepts used in linear motion systems and put them together here, as a sort of “linear motion basics” reference guide.

Unlike our curated lists of articles that address sizing and selection for specific products, such as ball screws, the articles below address more fundamental topics, such as Hertz contact stress, torsion, and the difference between moment and torque. And while you may not use all of these in every linear motion design and sizing project, understanding these foundational concepts can help you make more robust and cost-effective design choices.

Image credit: Newport

Some multi-axis systems can have six degrees of freedom and seven (or more) axes of motion. This article explains the difference between “axes of motion” and “degrees of freedom,” and why it matters.

Cartesian versus polar coordinate systems

In linear motion, we typically use the Cartesian coordinate system, but some applications — particularly those that use articulated robots — use the polar coordinate system. In this linear motion basics article, we explain how each coordinate system works, the differences between them, and how to convert from one system to the other.

Moment or torque – which do I want?

A force applied at a distance can create a moment or a torque. A moment force is static, whereas torque causes a component to rotate, so it’s important to know the difference between them and what causes each.

Rotational forces are defined as roll, pitch, and yaw, based on the axis around which the system rotates. For linear guides, roll, pitch, and yaw forces can cause deflection and errors in motion.

Image credit: E.V. Zaretsky, Glenn Research Center

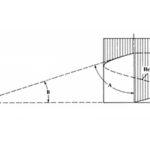

When two surfaces of different radii are in contact and a load is applied, a very small contact area is formed, and the surfaces experience Hertz contact stresses, which have a significant effect on a bearing’s dynamic load capacity and L10 life.

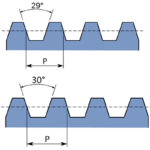

The location and shape of the contact area between a ball (or roller) and a raceway is determined by the amount of conformity between the surfaces. Understanding ball conformity is important, since it is closely tied to the amount of Hertz contact stress that a bearing experiences.

Because the contact area between a load-bearing ball (or roller) and its raceway is an ellipse, the velocity varies at different points along the contact area, causing the ball or roller to experience slip rather than pure rolling motion. This differential slip is directly related to friction, heat, and bearing life.

Tribology: Friction, lubrication, and wear

Lubrication helps to reduce friction in linear bearings, which is the primary cause of wear and, in many cases, failure. Tribology is the study of friction, lubrication, and wear, and explains the complex relationship between them.

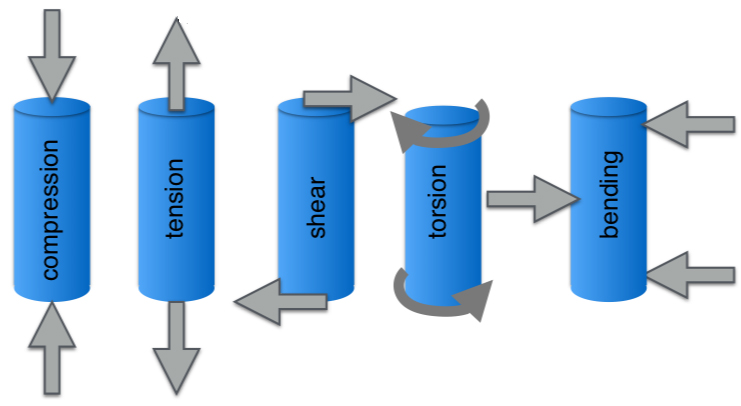

Tension and compression loads in linear motion systems lead to stress and strain in the materials. These concepts are especially important for components such as fasteners, which may reach their yield point or tensile strength limit before other signs of damage occur in a system.

Deflection in linear motion systems can lead to misalignment of components, excess forces, and premature wear and failure. In this article, we look at how a material’s stiffness and deflection are related, and how stiffness differs from strength.

Shafts on ball screws, pulleys, gearboxes, and motors can experience significant torsion, which causes shear stress and shear strain in the shaft. This article explains the effects of shear stress and shear strain and how to determine when a shaft will yield.

The hardness of a shaft or bearing surface plays a key role in its load capacity and life. In this article, we explain the different methods for testing and defining hardness.

Two commonly interchanged terms in linear motion are “inertia” and “momentum,” but they have different effects on a system’s performance. This linear motion basics article explains the difference between them and how each one is used in linear motion design and sizing.

Feature image credit: Bosch Rexroth

Inertia versus momentum

Inertia versus momentum

Leave a Reply

You must be logged in to post a comment.